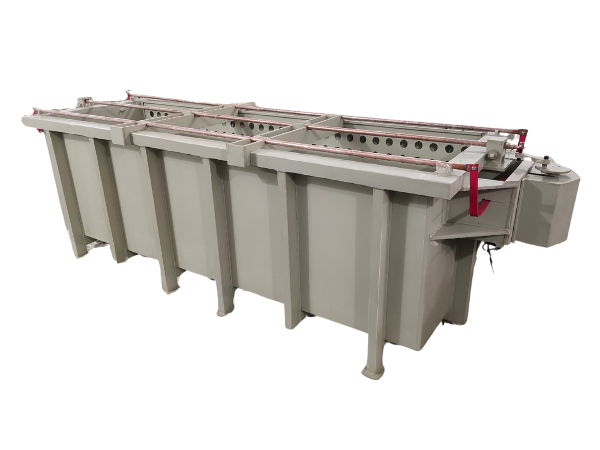

Tin plating tanks are specialized containers used in the electroplating process to apply a uniform, corrosion-resistant tin coating on metal surfaces. Constructed from high-quality, chemical-resistant materials, these tanks provide a controlled environment for precise and efficient tin plating. They enhance surface conductivity, improve solderability, and protect against oxidation, ensuring superior finishing quality. Designed for durability and long-term industrial use, tin plating tanks are widely utilized in the electrical, automotive, and manufacturing sectors, playing a crucial role in enhancing the longevity and performance of metal components.

Designed for precision and durability, tin plating tanks from Krushna Enterprises ensure a seamless electroplating process with uniform coating results. Made from corrosion-resistant materials, these tanks withstand harsh chemical environments while maintaining structural integrity. Their robust design supports efficient plating, improving surface conductivity and resistance to oxidation. Available in various sizes and custom configurations, they cater to diverse industrial needs, from electrical components to automotive applications. With a focus on quality and performance, these tanks provide a reliable solution for achieving superior metal finishing.

Office No. 7-B Vedant Edifice,

Dabhoi Ring Road. Soma Talav,

Vadodara - 390025.

Gujarat - India.

+91 92652 11766

sales@krushnaenterprises.com

Krushna Enterprises

Typically replies within minutes

How Can I Help You?

Chat With Us

🟢 Online | Privacy policy

WhatsApp us